In the aerospace industry, the pursuit of lighter, stronger, and more efficient structures is driving the adoption of advanced composite materials. In this context, Automated Fiber Placement (AFP) has become an essential technology, overcoming the limitations of manual methods and unlocking new possibilities for innovation.

Succesfully integrating AFP into production requires strategic vision, structured planning, and advanced tools.

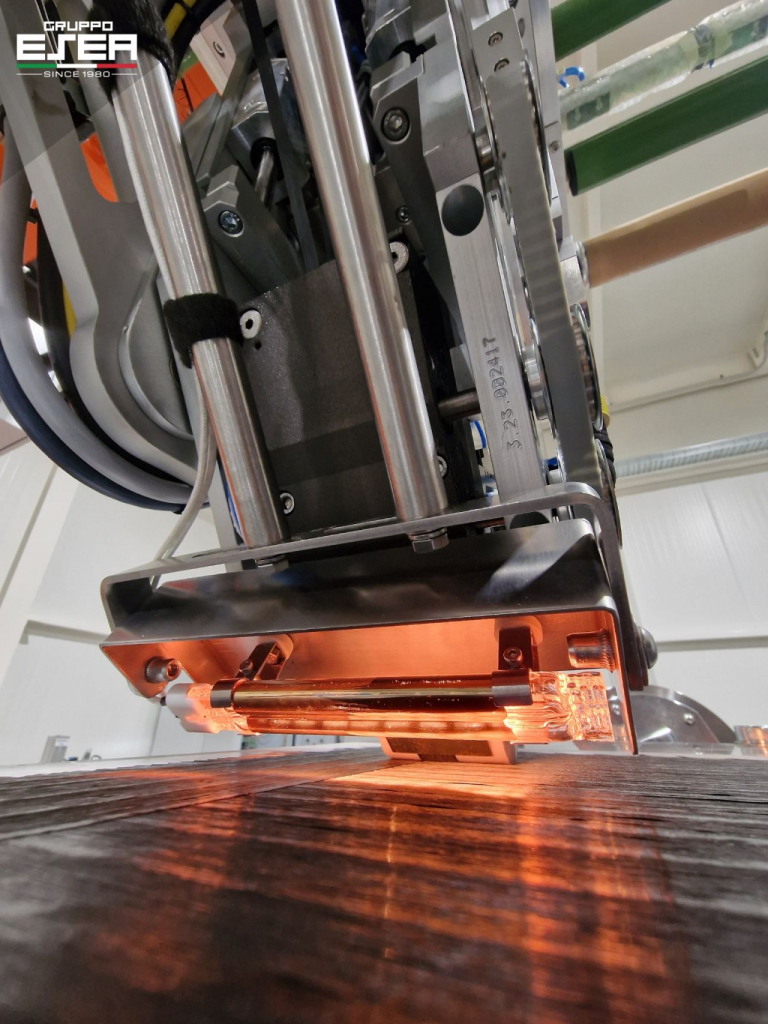

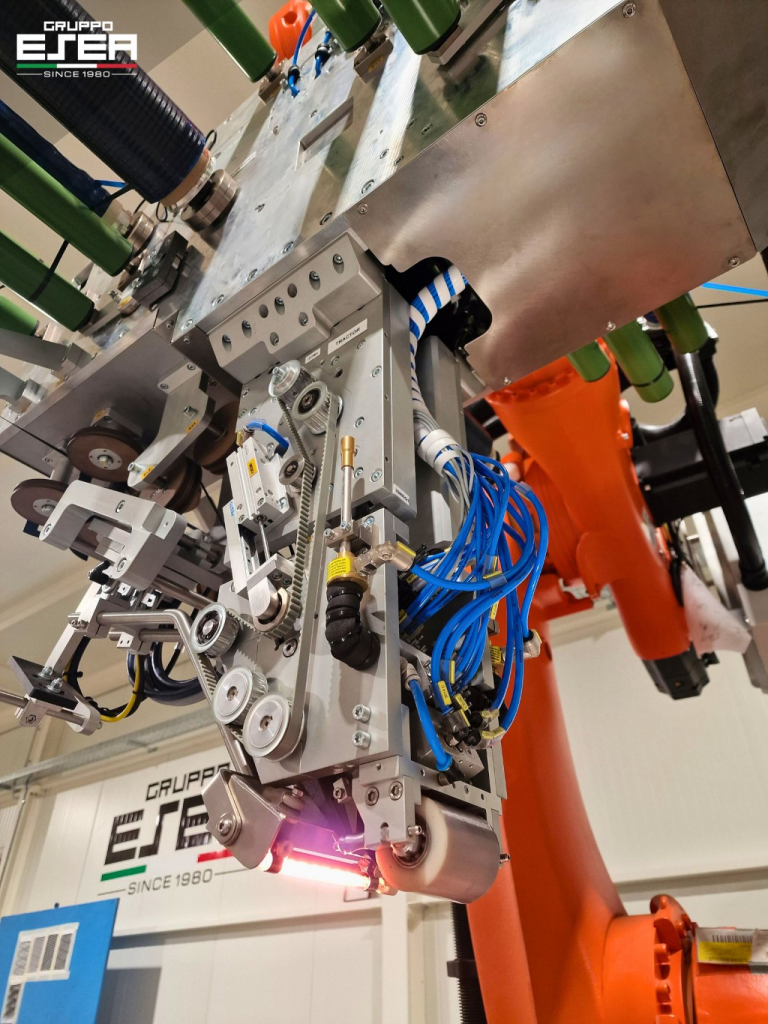

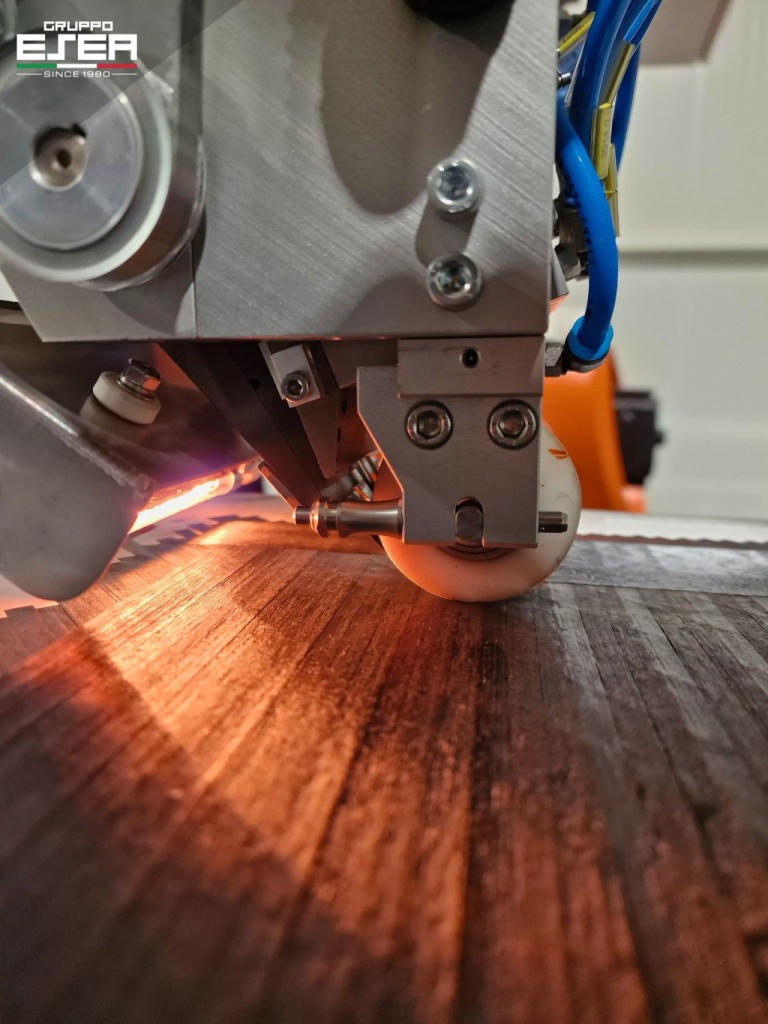

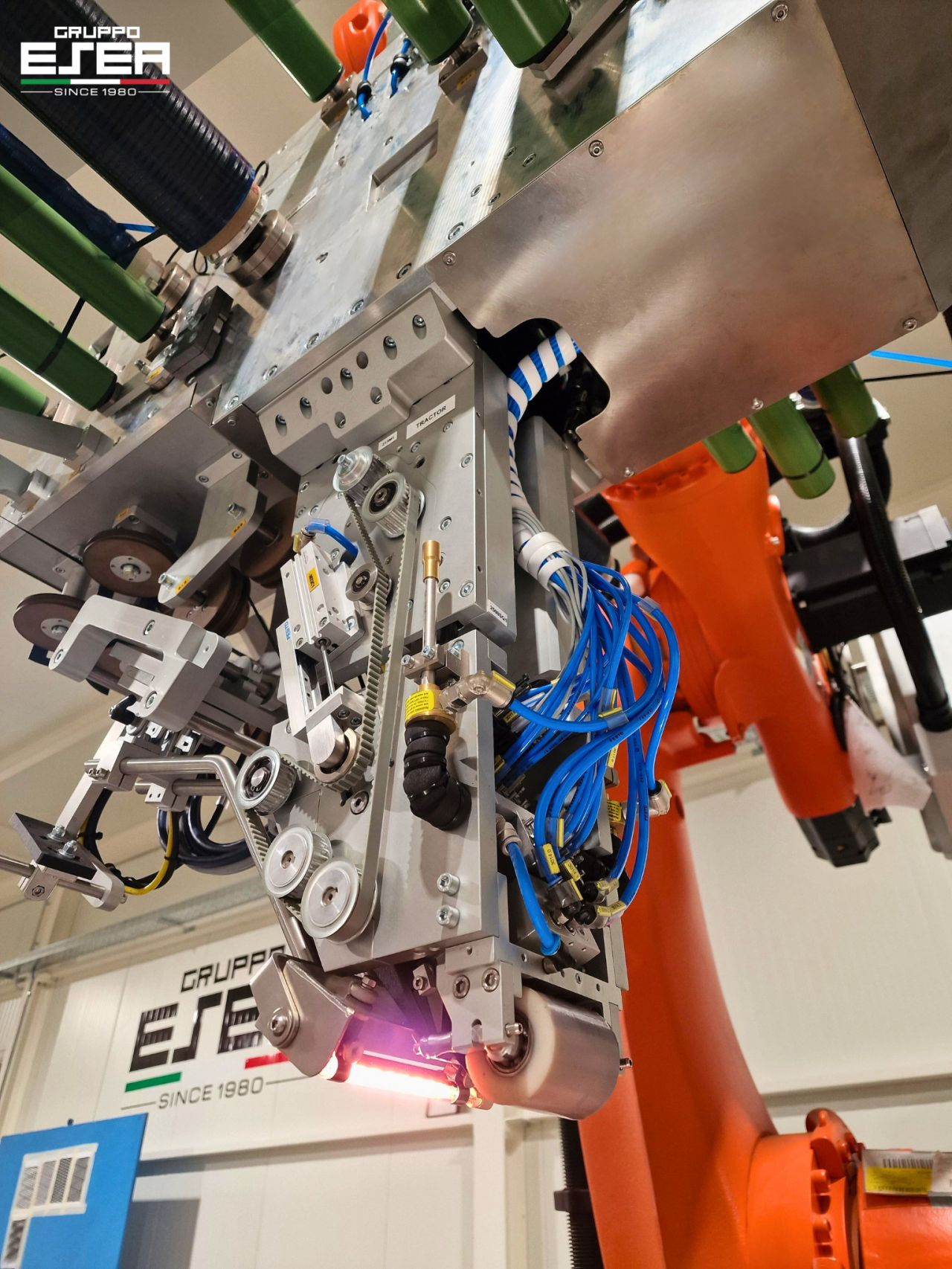

At the core of our approach is an in-house R&D laboratory, equipped with cutting-edge technologies, including our proprietary AFP machine “EFESTO” designed to maximize the potential of this groundbreaking technology at every stage of the production process.

• Identifying the Right components: We provide feasibility studies for individual components or entire finished products. This enables us to pinpoint the components best suited for AFP—such as wings, fuselage panels, and other critical structures—while optimizing time, costs, and performance.

• Simulation, Feasibility and Valitation: With “EFESTO” at the heart of our R&D lab, we can simulate, test, and validate every process before production begins. This ensures reliable, high-quality solutions that are ready to meet the most complex manufacturing challenges.

• Tailored Design Solutions: Once processes are validated in our lab, our AFP machines are delivered production-ready, customized to the specific requirements of our clients, and significantly reducing the time needed to ramp up production.

The synergy between our in-house R&D capabilities, AFP “EFESTO”, and our extensive expertise enables us to deliver innovative and fully customized solutions that empower our clients to succeed from day one.

We’ll be at JECWorld2025!

Visit us in Hall 6, Stand P100 to learn more about AFP “EFESTO” and how our advanced R&D lab is redefining aerospace manufacturing.