Esea Group

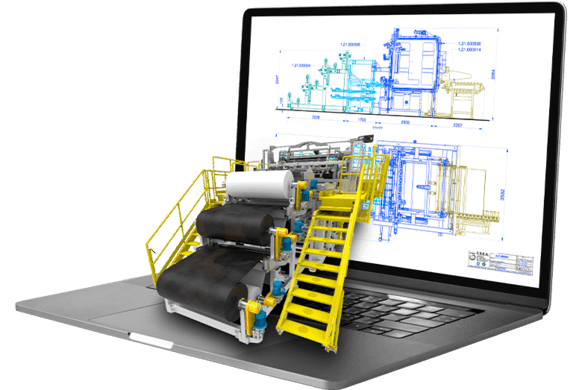

Customized Special Machines

Choose the experience of Gruppo Esea, leader in the production of special machines since 1980. Our engineers create innovative solutions tailored to customers, ensuring our success in a constantly expanding market.

Aerospace

We develop machining equipment for the production of European space launchers.

Read More ›

Comp. Manufacturing

We develop technologies for the automatic production of parts in composite material.

Read More ›

Hydrogen

We manufacture equipment for testing compressed hydrogen in composite tanks.

Read More ›

Defence

Build test benches in accordance with NATO standards and crates for transporting missile systems.

Read More ›

Pharma industry

Updating and training are our strength in Good Manufacturing Practices.

Read More ›

Automotive

We design and manufacture complete lines for component processing and assembly.

Read More ›

Mechanical and

Industrial Automation

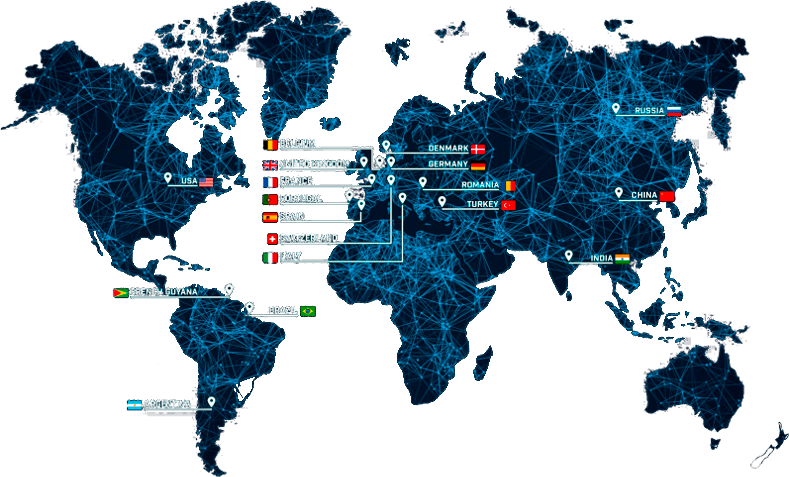

Machines installed worldwide

Research Lab

Research and development

ESEA has an in-house R&D laboratory, with a range of in-house test labs and production machines for all technologies in its portfolio.

ESEA forms partnerships with research centers to build the future of composite : our team of experts does most of our innovative research and offers versatile services to customers, helping them to choose equipment and to maximize the operating flexibility and production rate.

Commissioning, checks and periodic checks: discover the services of Gruppo Esea

The ESEA assistance department is able to support customers during on-site commissioning, offering a collaborative remote assistance system, via Augmented Reality, with undoubted advantages in terms of time and cost containment.

Last News

Projects and Events

Esea Group at Space Meetings Veneto 2024

Esea Group is preparing to participate in the internationally resonant event, the Veneto Space Meeting, scheduled for May 20-22, 2024. The event's...

Esea Group at the Jec World 2024

From March 5-7, 2024, Esea Group will participate in JEC World, the prestigious international trade fair taking place in the vibrant setting of...

Esea Group at Space Meetings Veneto 2023

From 15 to 17 May 2023 Gruppo Esea will be present at the Space Meeting Veneto event, three days dedicated to the theme of space and innovation.