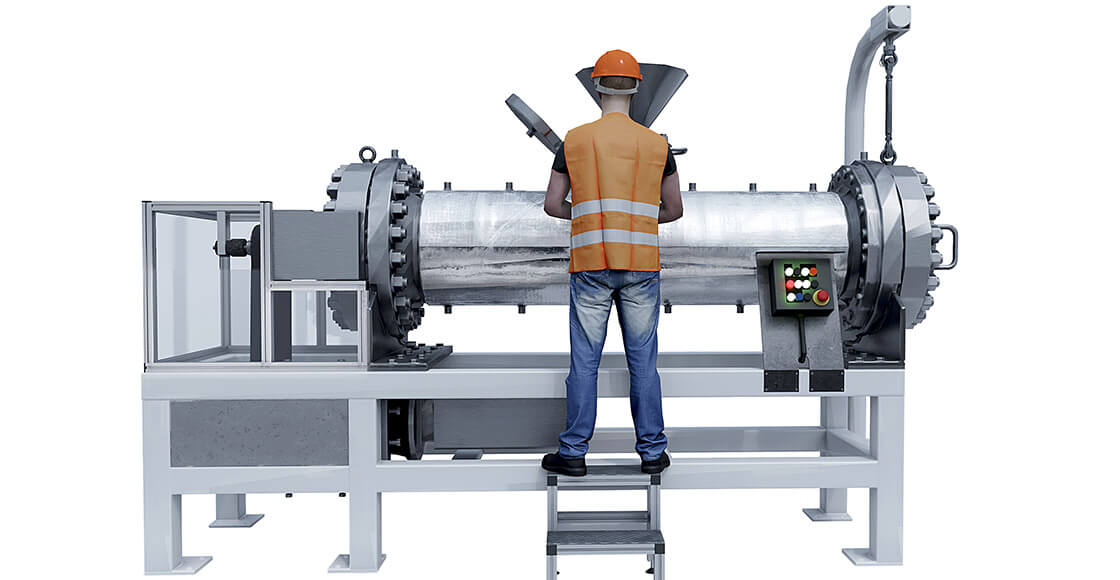

This line has been designed and built for the production of popping candies by pressurizing nitrogen.

The machine consists of:

- Flanged stainless steel tank SA 240 TYPE 304L ASME 2010 + A11

- Cooling jacket in AISI 304l stainless steel

- Product loading hopper in AISI SA 312 TP 304 stainless steel

- Rotating shaft with scraping blade with 10/100 holes for internal circulation of the cooling fluid

- Motorization unit consisting of a 400vca 1400g/m motor, mechanical speed variator and reducer to bring the number of operating revolutions between 25 ÷ 150 g / min

- Support frame of the reactor and motorization unit to be anchored to the support bench, made of painted steel.

- Double mechanical seal for high pressures approximately (60 bar – 130 c) for rotating shaft 25 ÷ 150 rpm. The mechanical seal can work dry or be lubricated with water at 3 ÷ 5 bar 80C °.

The seal is equipped with a safety pressure gauge with contacts for detecting excessive internal pressure. - Electric panel and control panel.

GALLERY