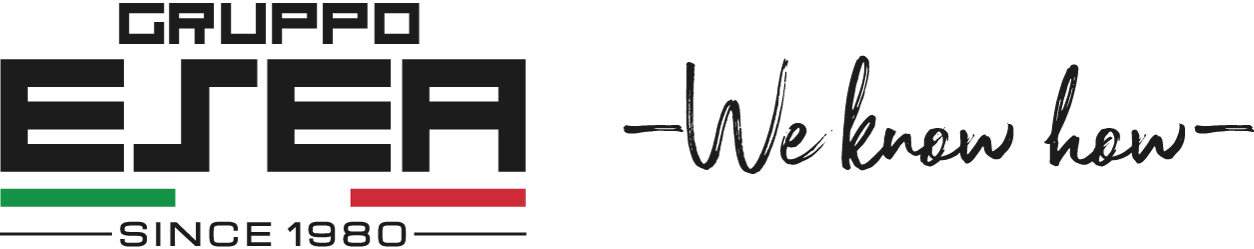

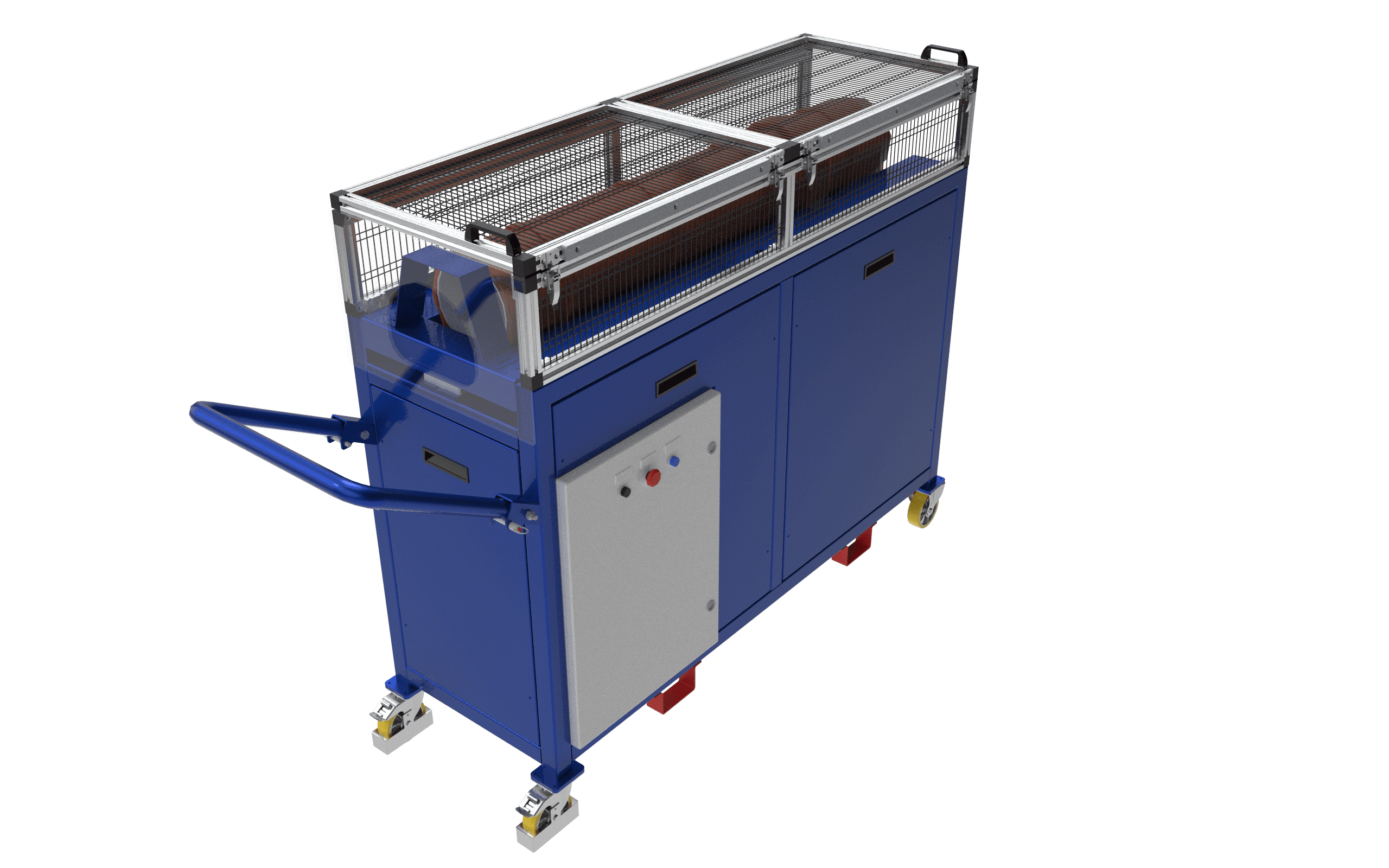

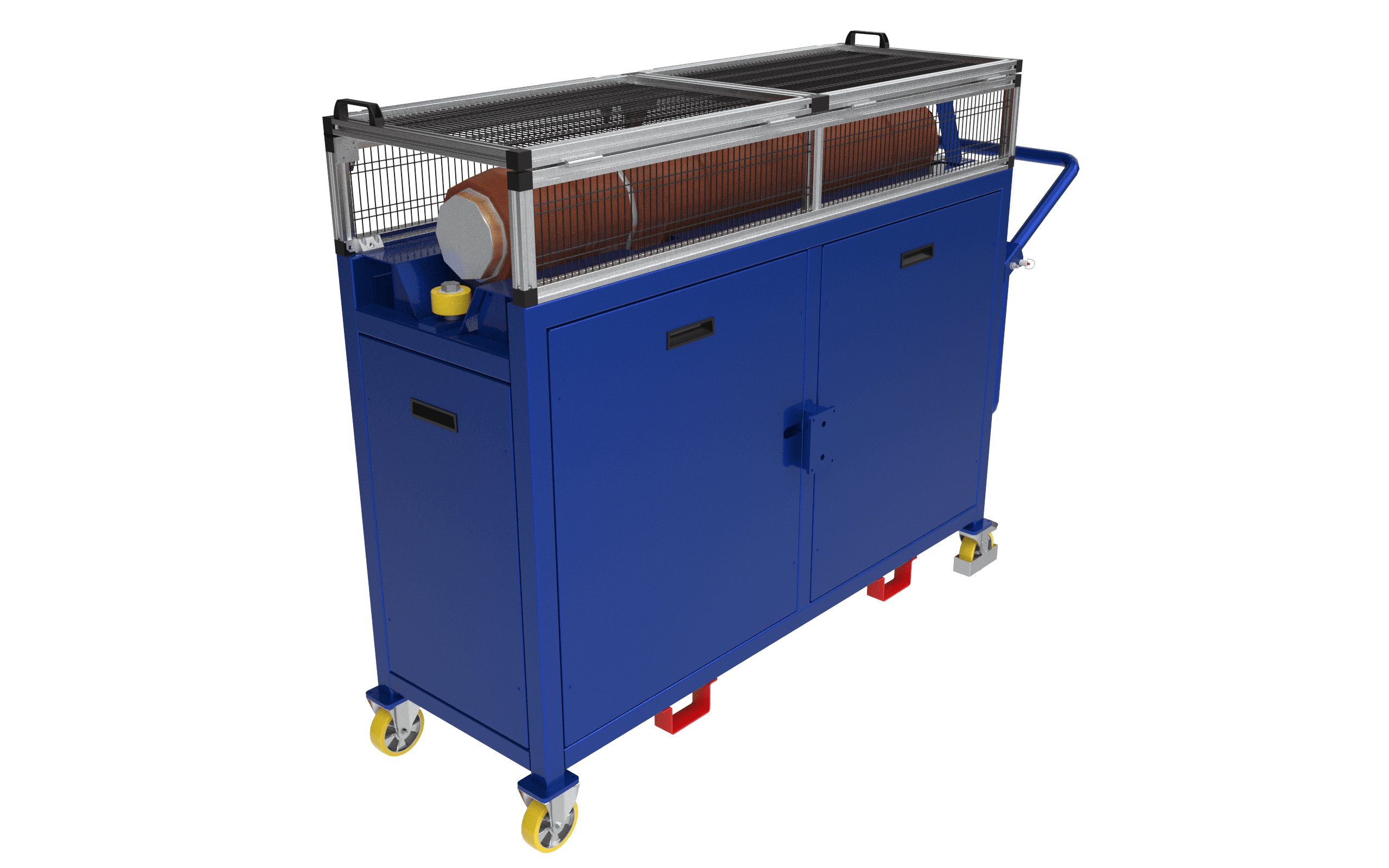

The trolley is designed to support the metal casing of a missile’s engine during the internal cleaning and chemosil application phases.

The pneumatic motor rotates the casing, while the thrust bearing system ensures the controlling of its movement.

The rotation speed is adjustable to optimize the process, with a maximum stop time of 1 second for operator safety reasons.

The necessary emergency buttons on both ends of the trolley are foreseen to immediately stop the engine in critical situations.

The rotation speed of the casing can be set between 5 and 20 rpm during the machine’s setup phases.