The machine was designed and built for the automatic feeding of cosmetic products to the quality control machine.

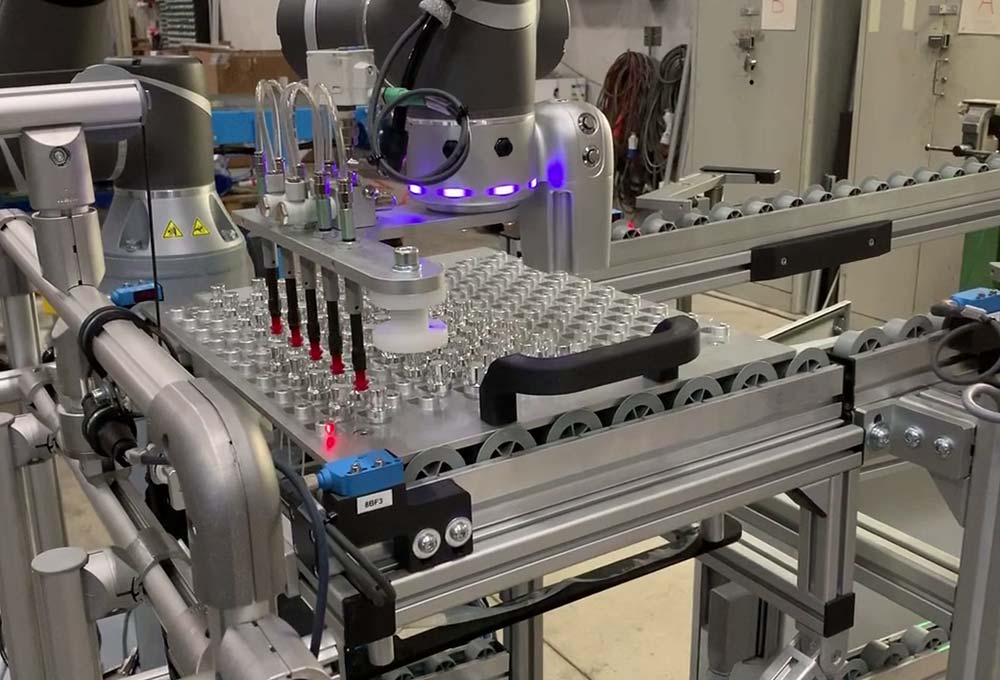

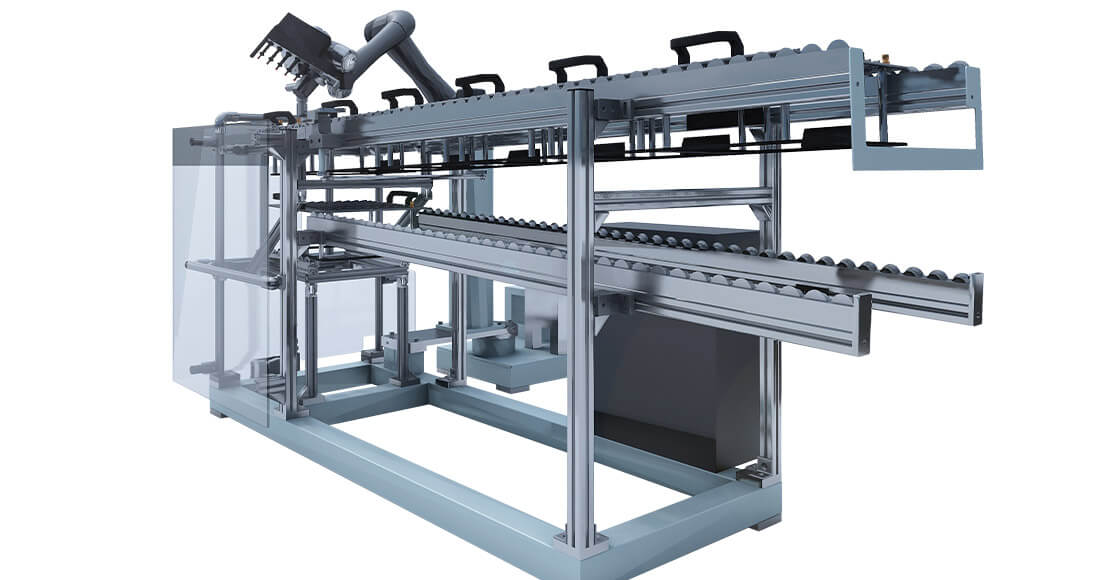

Specifically, the machine consists of gravity roller conveyors, aluminum pallets for transporting products, pallet singling system and an Omron collaborative robot designed to work alongside humans in safety, without barriers or protective cages to divide them.

During the loading phase, the operator places four pallets with the products inserted in the appropriate pockets and gives consent to evacuate

The incoming pallet is separated by mechanical levers.

The command for the singularizer is activated by the collaborative robot.

In the next operation, the pallet is centered on a lift with mechanical references for picking up the products.

The products are picked up (five at a time) by means of vacuum suction cups mounted on the robot gripper.

Once the robot has unloaded all the components from the pallet, by means of mechanical coupling, it will push the elevator down to be able to evacuate the empty pallet in the lower gravity roller conveyor. The elevator / descender consists of aluminum profiles, plastic guide wheels and a load balancing system with cable and pulleys.

The repositioning of the empty pallet on the upper roller conveyor for the new product loading is handled manually.

Gallery